Editor’s Note: This piece originally appeared on Metropolis magazine’s website as part of a content partnership.

Sometimes the impact of a single decision can ripple outwards, resulting in repercussions that far outweigh a project’s initial vision. That’s the case with Interface’s sustainability story. Back in 1994, the flooring brand’s founder, Ray Anderson, had an epiphany that the business needed to change its priorities and put the environment first. Just a few years later, Interface set out on Mission Zero®, a complete redesign of every aspect of their business with the goal of having zero negative impact on the environment by the year 2020—a goal the company achieved one year early.

“We quickly realized that Interface couldn’t fully pursue sustainability without engaging everyone who contributed to the success of our products—from our suppliers and employees to designers and end users,” said Chip DeGrace, Interface’s director of design purpose. “Ray wasn’t afraid to challenge the status quo—he wanted to inspire others to innovate and to consider how they could help Interface on our journey to sustainability.”

What Anderson didn’t foresee was that Interface’s quest to become a restorative company would end up reshaping the entire flooring industry and revolutionizing material recycling. Today, it’s commonplace to see products made with recycled content, but in the 1990s, sourcing recycled materials was a foreign concept for most businesses. It required rethinking manufacturing processes, machinery, and logistics, and when Interface declared it wanted to make products with recycled-content nylon, many of the company’s partners were skeptical. However, fiber manufacturer Aquafil saw an opportunity.

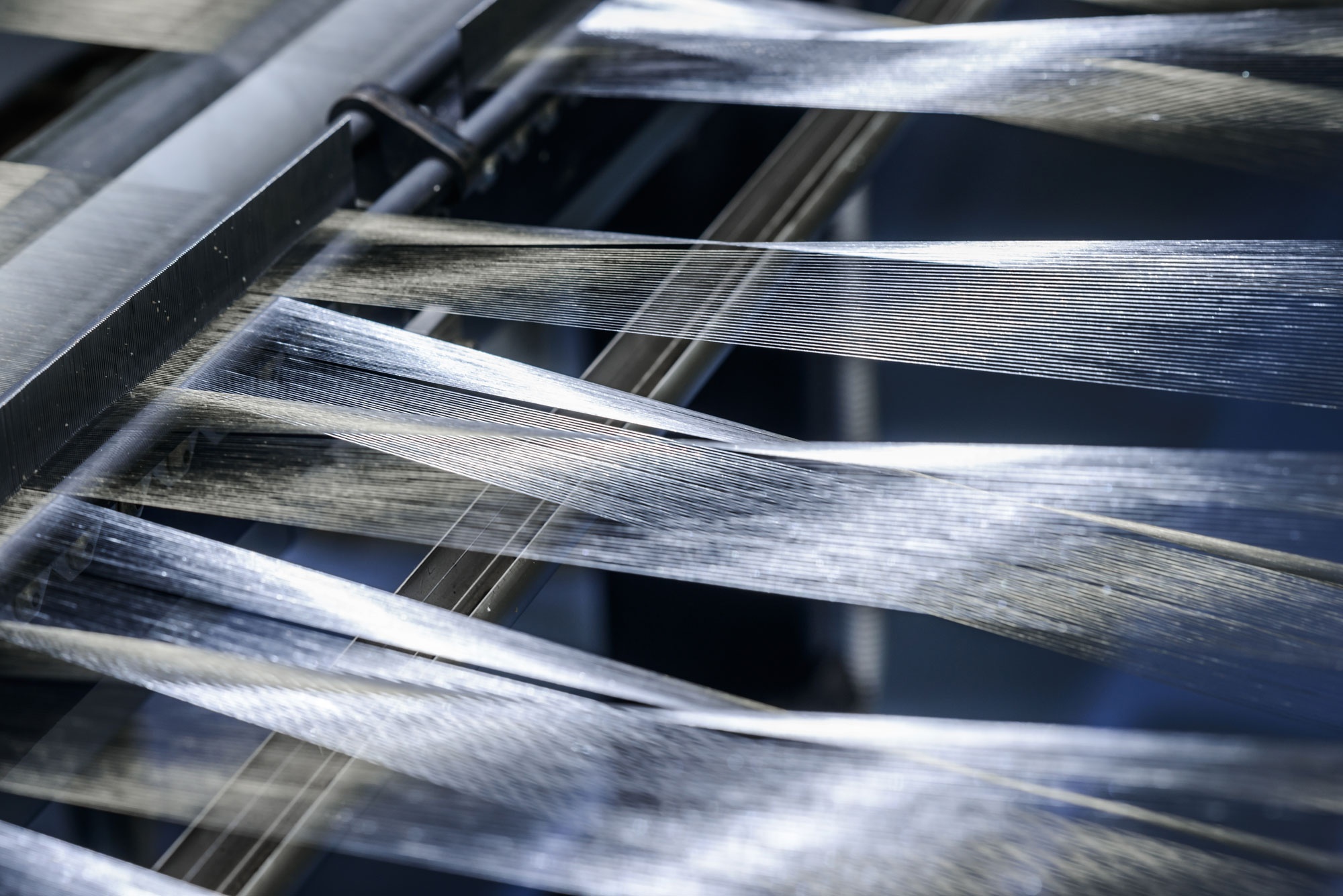

“Where others see waste, we see treasure,” said Giulio Bonazzi, CEO and chairman of Aquafil. “Our research and development team spent years designing a closed-loop system that would allow nylon made 100 percent from waste to be regenerated an infinite number of times without affecting the product’s quality or performance. The success of our ECONYL® regenerated nylon shows that designing for the good of the planet can also be good for business.”

Interface’s partnership with Aquafil has allowed both companies to have a much larger impact than they ever considered back in the 1990s. Aquafil introduced its ECONYL nylon, which is made from waste like old carpet, textile scraps, industrial plastics, and fishing nets, in 2011. Interface began using the recycled-content nylon immediately, and other carpet manufacturers followed suit. Over a four-year period, the innovation reduced the nylon yarn industry’s carbon footprint by 334,000 metric tons.

“Aquafil recognized that solving recycled-content nylon and partnering with Interface could position them for growth in new markets,” said DeGrace. “Thanks to their development of ECONYL nylon, we now have the ability to source 100 percent recycled content yarn, which plays a huge role in helping us produce the lowest carbon footprint carpet tiles before offsets.”

By 2012, demand for ECONYL nylon grew so strong that Aquafil began seeking new sources for recycled materials. At the same time, Interface was interested in starting a social initiative that would benefit communities as well as the planet. This led Interface to join forces with the Zoological Society of London to create Net-Works—a program that empowered communities to collect old fishing nets that are then sold to Aquafil for regeneration into ECONYL nylon alongside other waste materials.

Between 2012 and 2020, the Net-Works program collected over 300 metric tons of waste fishing nets, providing more than 2,000 families with access to new income and protecting over 5,000 hectares of ocean. In order to boost its impact, in 2021 Net-Works was spun-out as Coast4C, a social enterprise that has helped the communities form an inclusive supply chain for both regenerative seaweed and fishing nets.

“Net-Works is an example of how collaborations can yield system-level transformations that benefit business, people and the planet,” said DeGrace. “It’s a powerful illustration of what’s possible when multiple entities come together—the final result was greater than any of us could have achieved on our own.”

Partnerships like that of Interface and Aquafil make meaningful change possible. What began as one company’s ask for the “impossible”—recycled-content nylon—has forever changed the flooring industry and continues to impact furniture and high fashion, with dozens of brands like Prada, Burberry, Adidas and more making products from ECONYL regenerated nylon.

“There is power in asking for what you want,” said DeGrace. “Whether you are a manufacturer sourcing raw materials or a designer creating vendor specs, remember that you can be the catalyst for positive change.”