A major decision in the design of any space is the type of flooring you choose. Also, since flooring often makes up a major portion of the project budget, it’s a choice that shouldn’t be taken lightly. This article will help you to make an informed decision when buying carpet tiles for your next commercial project.

What is considered a good-quality yarn?

When choosing a carpet tile for your organization, you may come across the term “solution-dyed”. If not, you should be asking about this to your vendor– because it is important. Solution dyed fibers with a low modification ratio mean longer life of carpet tiles. Check out the below features to learn more.

What is solution-dyed yarn?

The term refers to a method used to dye the carpet fibres. In short, it is more than skin deep. Solution dying injects fiber with color throughout, not just on the surface.

Non-solution dyed fiber is like a radish, with only surface color. Solution-dyed fiber is like a carrot, colored throughout.

Benefits of solution-dyed yarn

Color lasts longer, resisting most bleaches and other harmful liquids as well as sun exposure. And with the stain resist technology that’s built into the fibers, you’ve got added protection against staining with no need for an additional topical treatment.

The fiber we choose has got a big job to do—work hard, lower our environmental impact and look beautiful for a very long time. So, we purchase from leading manufacturers who provide premium, solution dyed fibers with a low modification ratio.

Low Modification Ratio vs High Modification Ratio

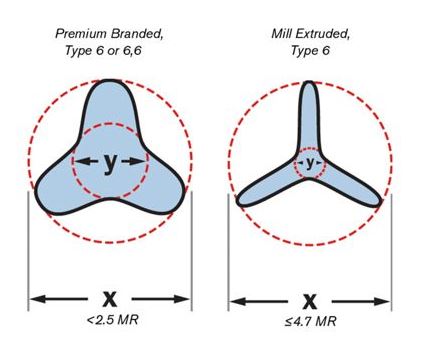

Modification ratio estimates a fiber’s performance by how “round” it is. By that it also refers to the strength and durability of the fiber. Here, the roundness indicates the best modification ratio that can be achieved for giving an exceptional performance.

The premium branded fibers used by Interface significantly reduce flattening and crushing over time due to foot traffic, leading to a longer useful life. And, it offers soil hiding capabilities.

Modification ratio considers the inner (y) and outer (x) circles as noted above. The lower ratio means that a fiber has more surface area and less room to trap soil and dirt.

The fibers we use have a modification ratio of 1.5 – 2.1, whereas mill extruded Type 6 Nylon has a ratio of as much as 4.7.

Air Entangled Yarn Bundle

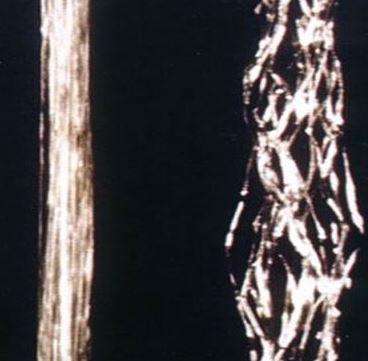

The yarn used in all carpet manufacturing comprises of a bundle of several individual strands or fibres. The individual strands are passed through a tube into which air is blown. This process entangles the single yarn at 2-3 centimeter intervals to form a yarn bundle. This way the used fibre in carpet tiles is textured to provide “spring” and allow the fibre to recover under foot traffic or heavy load.

Normal Yarn Fibre Bundle vs Air Entangled Yarn Fibre Bundle.

Passing the Test

We go beyond standard wear and tear testing with our Colour Fastness Test (Test designed to access colour change caused by light & wear on carpet surface), Castor Chair Test (Test designed to simulate effect of castor chairs used in commercial spaces on carpet) and Vetterman Drum Test (Test designed to simulate constant walking traffic). [Download the above test certificates for a better view].

We simply won’t release a product that doesn’t pass our rigid wear testing standards.

Check out our Carpet Tiles collection to learn more.