Interface is now a Carbon Neutral Enterprise. In other words: we’re a carbon neutral company making carbon neutral products.

As our CEO, Laurel Hurd, puts it: “Now everything we do, every aspect of our business, is carbon neutral. We have worked tirelessly to radically decarbonise, tapping into our culture of innovation and design, resulting in what we believe are the lowest cradle-to-gate carbon footprint carpet tile products on the market, even before applying offsets.

We are incredibly proud of this achievement, and we’re not stopping here. We will continue to decarbonise even further. Reduce first, keep reducing, and balance what’s left with credible offsets, until those offsets are no longer necessary. That is our way.”

Becoming a Carbon Neutral Enterprise is the latest milestone in a long track record of transforming our factories, products and supply chains to dramatically reduce our carbon emissions. But how did we do it? First, we’ll take a look at our approach.

Defining our Approach to Carbon Neutrality

With a number of carbon neutral claims being made in the built environment and beyond, at Interface we chose to be certified as a Carbon Neutral Enterprise according to the PAS 2060 standard. PAS2060 is the leading international standard on carbon neutrality created by the British Standards Institution (BSI). We strongly believe in verifying our carbon management plans, as well as emissions and carbon credits, against rigorous, internationally recognised standards.

According to BSI, “Carbon neutrality means not adding new greenhouse gas (GHG) emissions to the atmosphere. Where emissions continue, they must be offset by absorbing an equivalent amount from the atmosphere.”

For Interface, this means finding ways to reduce the amount of carbon emissions produced through our operations, product manufacture, and relationships with our suppliers and customers. After exhausting these means, we then offset what we cannot eliminate. This route allows us to create an absolute balance between the carbon we emit and the offsets we use.

Measuring our Existing Footprint

The reality is that you can only manage what you measure. So, how exactly is the carbon footprint of a company measured?

There are a standard set of rules called the Greenhouse Gas Protocol (GHG Protocol), under which all emissions made by companies are split into three categories:

| Direct or Indirect | Type of emissions | Examples | In other words | |

| Scope 1 | Direct Emissions | GHG emissions directly from operations that are owned or controlled by the company | On-site energy generation

Fuel for company cars |

What you burn for energy/fuel |

| Scope 2 | Indirect Emissions from Purchased Energy | Indirect GHG emissions from the generation of purchased or acquired electricity, steam, heating, or cooling | Renewable electricity | What someone else is burning for you for energy |

| Scope 3 | All other Indirect Emissions | All indirect emissions (not included in scope 2) that occur within the supply chain (upstream) or customers (downstream) | Use of sold products

Purchased goods and services Employee’s commuting to work |

Everything else |

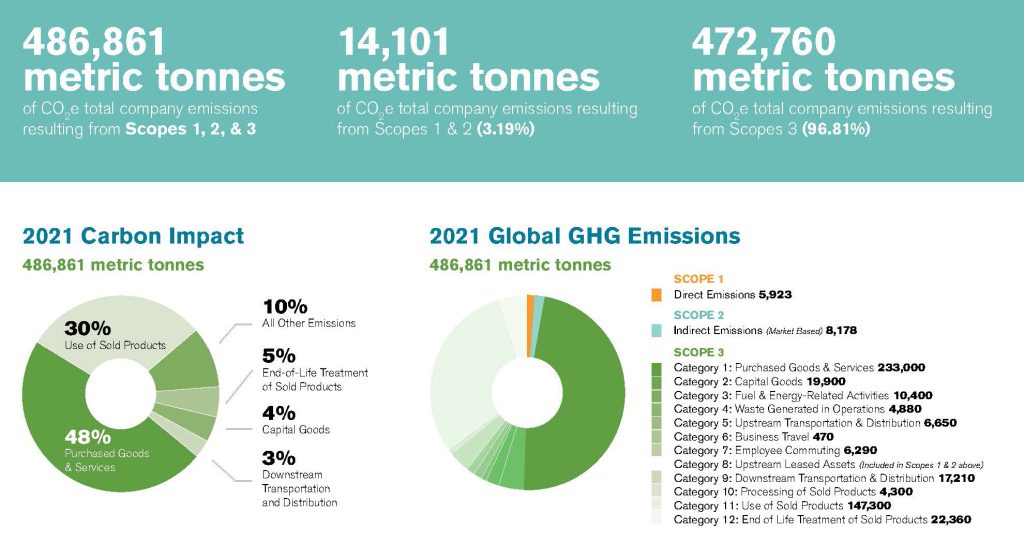

For most companies, and especially manufacturers, the majority of your emissions are within the Scope 3 category. With Interface, for example, in 2021, only around 3% of our emissions were in Scopes 1 and 2.

Here’s our breakdown:

Making Measurable Change

At Interface, we’ve been able to increase our use of renewable energy – with 75% of all energy (electricity and gas) for our factories coming from renewable sources. By seeking alternatives and even generating our own power with onsite solar panels in our Netherlands and Australia factories, we have reduced our reliance on fossil fuels.

In September 2022, Interface was awarded the Beyond 100% award at the RE100 Leadership Awards for ensuring that 100% of the electricity we use in our factories globally is from renewable sources and for our commitment to reducing the operational and embodied carbon aspects of our business.

However, the biggest impact is within our supply chain, with 48% of our impact relating to purchased goods and services. To tackle and reduce these emissions, we need to work with our suppliers to encourage the use of renewable energy, circular solutions and other avenues for decarbonisation. We have seen some great success through bringing our suppliers together for summits to discuss common challenges and using online platforms such as Manufacturing 2030.

See part two of this blog series, in which we take a look at our work to make our products carbon neutral.

Are you working towards becoming a carbon neutral company? We’d love to hear about your sustainability journey, so get in touch. Or, find out more about how we’re implementing sustainable solutions.