A new vision for plastics: green chemistry, the circular economy, and a climate fit for life.

When reviewing recent news about plastic waste filling the oceans, toxic additives leaching from plastic products, and the impacts of fossil fueled global warming, making a plastic product – like Interface’s modular flooring – sustainable can begin to seem like an impossible task. But resolving that contradiction has been at the heart of Interface’s sustainability mission for over 20 years. As Ray Anderson often said, “If we can do it, maybe anyone can.”

In this spirit, Interface convened a group of stakeholders at a Sustainable Plastics Symposium in San Francisco this summer, including experts in green chemistry, the circular economy, and life cycle assessment (LCA). Symposium participants came together around a shared goal of creating a set of criteria to define sustainable plastics in a holistic way that goes beyond a Red List approach.

If only making a plastic product healthy and sustainable were as easy as making sure it had no Red List ingredients!

Green Chemistry

Dr. Lauren Heine of Northwest Green Chemistry, known for developing the GreenScreen for Safer Chemicals and the EPA’s Cleangredients database, started off the expert panel by showing three NGO efforts to define sustainable materials. Each effort uses different terms, but all agree that in addition to using safer chemicals in products and processes, we need to consider the ability to reuse a product at end-of-life and its overall environmental impact or we’ll have exchanged one problem for another.

Circular Economy

Dr. Mike Biddle, known for developing the world’s first at-scale mixed plastic recycling technology as founder of MBA Polymers, emphasized that plastics are often the best material choice for lightweight and durable performance. However, unless the disastrous impacts of plastic waste filling the oceans can be solved, plastic products can never be sustainable. Biddle pointed out that while most plastics are technically recyclable, very few actually get reclaimed or recycled in a circular economy. According to Biddle, using recycled plastic not only keeps it out of the oceans, but also allows us to have all the performance advantages of plastic with 80-90% less energy use (and 2-4 tons less contribution to global warming per ton of recycled plastic).

Embodied Carbon

Kirsten Ritchie, Sustainable Design Principal at Gensler, shared her pioneering work using LCA data from Environmental Product Declarations (EPDs) to guide product selection. She emphasized that EPDs allow designers to understand the contribution the products they select have to global warming. According to the Centers for Disease Control and other experts, nothing is more important to public health right now than stopping global warming. Ritchie’s analysis showed that carbon footprints of carpet tiles vary by over 2X within a single manufacturer’s line and by as much as 5X between manufacturers.

Connie Hensler, Interface’s Director of Life Cycle Assessment Programs, then used the type of criteria described by Heine, Biddle, and Ritchie to demonstrate that once we look at plastic products holistically, we may come to new conclusions. As an example, Interface’s standard GlasBac carpet tile products contain 9-10% PVC plastic in their backing, which is one of the few petrochemical plastics included on the Living Building Challenge Red List. But after more detailed analysis, well-managed PVC turns out to be the best choice for modular plastic flooring.

Interface carpet tiles on GlasBac backing:

- Green Chemistry: Interface has eliminated all formaldehyde, phthalates, heavy metals, and fluorocarbons from these products while reducing the amount of virgin PVC consumed to make a tile by 57%.

- Circular Economy: Interface has designed a 3rd party-verified closed loop system for this backing. We process millions of pounds of vinyl backing every year into new GlasBacRE carpet tile backing. Products on GlasBacRE contain 80-89% recycled content and no virgin PVC.

- Life Cycle Assessment of Environmental Impact: Interface products on GlasBac and GlasBacRE have the lowest average carbon footprint of any standard carpet tile platforms in the US as a result of very high recycled plastic content and the use of 96% renewable energy in manufacturing.

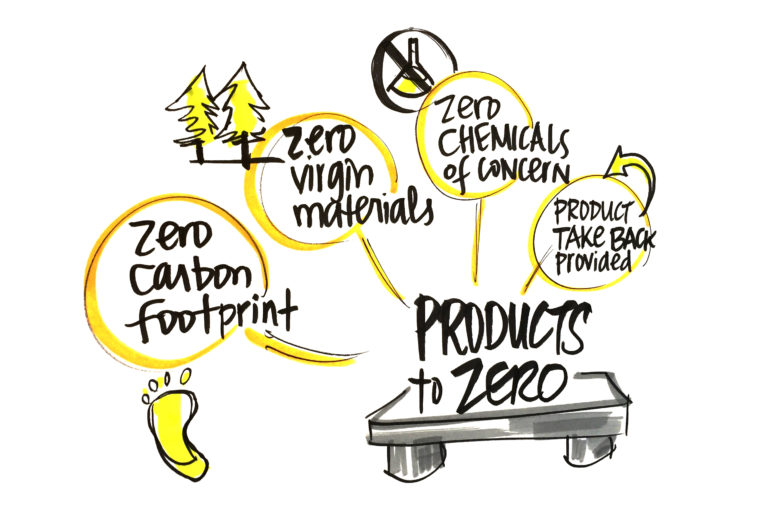

A New Approach to Sustainable Plastics

The goal of the Sustainable Plastics Symposium in San Francisco was to begin to engage subject matter experts and other stakeholders in creating an approach that moves the marketplace past outdated ways of product assessment that can create unintended and regrettable trade-offs. If an entire “system” for determining how healthy and sustainable a plastic product is consists of single question (“Is it PVC or non-PVC?”), a product may end up being selected that contributes to other types of toxicity, will never be recycled, and contributes disproportionately to global climate change. At the end of the day, this product’s only “green” claim will be “PVC-free” or perhaps “Red List Free.” Those who participated in the Symposium aspire to see plastic products do much, much more.

We’re committed to developing tools that will help our customers choose the best plastic products. This commitment will lead us to host other symposiums and participate in other forums. Recently, Interface joined a historic panel discussion at the Living Product Expo in Pittsburgh, Pa. to discuss the future of PVC plastic with leaders from Perkins+Will, Healthy Building Network, Tarkett, and Construction Specialties. We’re working to identify a path for improving PVC production and use today while looking toward a future where products are made without virgin petrochemical plastics.

Interface shares the vision of the Living Product Expo: a future where products make the world better, not just less toxic, less wasteful, or less polluting. And we have confidence that products like ours can be part of that positive future. If Interface can make a plastic product that is free of petrochemicals, removes plastic from the oceans, and helps create a climate fit for life, maybe anyone can.