What’s hot in green building right now? No, global warming isn’t hot, despite growing alarm about extreme weather events. What’s hot is health. Specifically anything related to the potential health impacts of building products.

The rise of the WELL Building Standard and the addition of a day-long Materials and Human Health Summit to Greenbuild provide two data points supporting this overall trend. Despite growing interest and a host of new tools, the expansion of the health trend beyond simplistic building material “Red Lists”, and into more comprehensive, transparency-based material assessments, is still in its infancy. Many architecture and design firms aspire to do material health screenings, but lack the technical expertise or established processes to consistently add this element to their already-strained project budgets.

As a frequent speaker on this topic, including both Greenbuild Materials and Human Health Summits, I offer three questions that need to be considered as firms begin to engage manufacturers in an effort to identify “healthy” products.

What’s in your product?

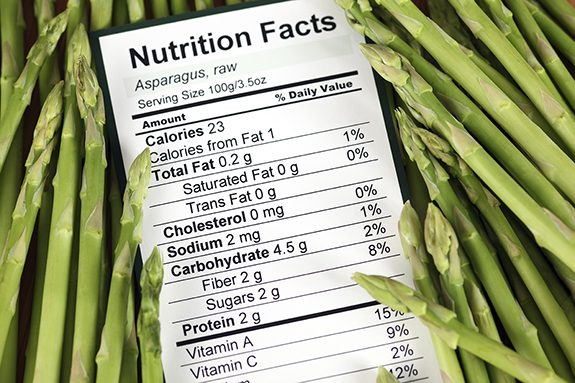

This question forms the foundation for understanding what possible health issues a product might present when used in a building. Many new tools are being developed to help manufacturers disclose ingredients in a consistent way. But even the confusingly-named Health Product Declaration (HPD) format doesn’t actually tell you whether a product is healthy – it just tells you the ingredients. Many of the tools like HPD aspire to become as standardized and broadly used as the Nutrition Facts Label we find on packaged foods, but the fact that a box of cookies discloses their Nutrition Facts does not make them healthy. It does, however, allow for more informed choices about what you buy, which is the true value of standardizing transparency.

What comes out of your product?

This is an important question because many building product ingredients, if you gargled with them every day, would seriously damage your health. Yet the vast majority of these ingredients are used in such a way that there is no foreseeable way for a user to be exposed to them. This is the big difference between ingredients in a building product and ingredients on a Nutrition Facts Label; for a Nutrition Fact Label, exposure is a given (or what’s the point?).

The big difference between ingredients in a building product and ingredients on a Nutrition Facts Label? On a Nutrition Fact Label, exposure is a given.

The question of likelihood of exposure to ingredients in plastics and other building materials is fraught with technical questions that live in the complex world of toxicology and risk assessment, so I would like to offer a common-sense alternative: focus your analysis on materials that (1) release volatile organic chemicals (VOCs) or (2) receive heavy wear and abrasion during use.

VOCs

VOCs, by nature, are emitted from the product, so some level of exposure is guaranteed. Anything you smell is releasing VOCs into your nose, ranging from the wholesome and harmless (fresh baked bread) to the carcinogenic (formaldehyde).

Fortunately, green building standards, with help from the California Department of Public Health, have now standardized tests for the most worrisome common VOCs released from interiors products. Numerous industry standards (e.g., Green Label Plus for carpet, FloorScore for hard surface) are harmonized to the strict California standards (CA 01350), so finding low-offgassing products has become as easy as looking for the right certification.

Chemicals used in high-touch surfaces

The second category, chemicals used in high-touch surfaces, becomes more complex because exposure only occurs over time and only under the right conditions, usually when repeated washing and abrasion of surfaces causes ingredients to migrate out and end up in dust. The most famous recent example of this is highly toxic and persistent flame-retardants migrating out of furniture and electronics over time. While some potentially hazardous chemicals break down quickly outside the product, usually broken down by microbes, others are highly persistent (no critter yet seems to have acquired a taste for polybrominated flame retardants) and accumulate in the environment over time.

PFCs

In carpet, the high-touch surface is the face fiber, usually nylon, which is often coated with a stain and soil resistant chemistry based on perfluorinated compounds (PFCs). Due to the toxicity of some members of this chemical family and the persistence in the environment of all PFCs, they were recently added to the Living Building Challenge Red List. Increasingly, premium brands of carpet yarn are moving to integrally stain resistant nylon that requires no coatings that can wear off over time. Interface Americas received an award from Environmental Building News in 2011 for producing the first PFC-free carpet tile platforms and is PFC-free in all products.

Interface Americas is PFC-free in all products.

How is your product made?

Finally, health impacts that might affect the end users of a product are but a small piece of the healthy product puzzle. Many of the worst health impacts associated with the life cycle of a product happen far from the comparative tranquility of a school or office environment. Exposure occurs in the mines, oil and gas drilling operations, chemical refineries and plastic factories that supply the raw materials that ultimately make up the products we manufacture.

Plastic products traditionally come from chemicals derived from oil, gas, and coal as well as from mined mineral fillers. The air and water pollution associated with resource extraction and refining are typically thought of as environmental impacts, but for the people who live and work nearby, they are definitely health issues. Is a Red List Free product still a “healthy” product if its ingredients come from natural gas fracking that left the local water supply tainted by heavy metals and petrochemicals?

At Interface, we see increasing recycled content and end-of-life recycling as the only viable solution to the many systemic pollution issues associated with the lifecycle of products made from oil, gas, and mineral resources. When a product comes from 80% recycled content, it allows us to know we’re doing our part to address the effect industrial operations have on their surrounding communities.

When a product comes from 80% recycled content, like our Net Effect™ Collection, we know we’re doing our part to address the effect industrial operations have on their surrounding communities.

Staying out of the fear trap

The way most of the discussion of healthy buildings is going, we are quite focused on eliminating the negative impacts building products might have on our health. But we also know that becoming chronically stressed, in this case about all the toxic chemicals in the world, is not good for your health. The challenge is to find your own “Goldilocks” level of worrying that keeps you motivated to change our industrial system without living in constant fear.

I find that it helps to spend equal time on the positive side of the health equation, investigating all the ways interiors products can be designed to help enhance building occupants’ well-being, boost their productivity, and ameliorate their stress levels. So when thinking about toxic chemicals has you down, I recommend picking up Terrapin Bright Green’s report The 14 Patterns of Biophilic Design, and pondering all the ways interior products and designs could help people feel as healthy and productive as when they are outdoors. Because after all, designing products that won’t expose you to toxic chemicals is truly only the beginning of the exciting work of designing spaces conducive to health and happiness.